Оценка на подходящи локации за модулно строителство на къщи

Изборът на подходящо място означава да се обърне внимание на лесното му достигане, състоянието на терена и дали вече има инфраструктура. Места със стръмни склонове или лошо дренажиране често изискват скъпо поравняване на терена, преди да започне каквото и да е друго. Равна земя до съществуващи пътища спестява много време за подготовка към строителство. Последните спецификации от търговски организации всъщност подчертават необходимостта от проверка на транспортните маршрути за модулите. Виждали сме проекти напълно да заседнат, защото товарни камиони не могат да минат през тесни улици или удрят горната част на стари мостове по пътя.

Разбиране на законите за зониране и ограниченията за използване на земя за модулни къщи

Зонирането често е истински проблем за собствениците на модулни къщи. Повечето райони в страната (около 48 щата) вече признават тези къщи като постоянен адрес, но много градове все още имат свои собствени правила относно размера или външния вид на сградите. Преди да предприемете каквито и да било стъпки, проверете с местните органи дали има разлика в начина, по който се третират модулните къщи и традиционно построените къщи, когато става въпрос за строителни правила. Консултация с градски планировчици в ранен етап може да спести много време в бъдеще, тъй като около две трети от закъсненията при одобренията се дължат на неразбиране на изискванията на местните закони.

Провеждане на проучвания за приложимост на обекта: наклон, почва и достъп

Подробното проучване за приложимост включва:

- Анализ на наклона : Обектите с наклон над 15% обикновено изискват укрепващи стени (8 000 – 20 000 долара)

- Анализ на почвата : Почви от разширяваща се глина могат да изискват по-дълбоки фундаменти (+20% разходи)

- Достъпни пътища : Доставките изискват височина от 14 фута и ширина на пътното платно от 12 фута

Проучването на модулното строителство показва, че 40% от превишаването на бюджета идва от недостатъчни проучвания на обекта.

Осигуряване на инфраструктура и достъп до комунални услуги, подходящи за модулно строителство

Потвърдете, че водоснабдяването, канализацията и електрическите връзки отговарят на спецификациите за фабрично производство. За обекти извън мрежата може да са необходими септични системи (10 000–30 000 долара) или пробиване на кладенец (15–50 долара/фут). Координирайте доставчиците на комунални услуги още в проектната фаза, за да избегнете промени след монтажа. Превантивното планиране намалява проблемите с връзките с 70% в сравнение с традиционното строителство.

Основни разходи за подготовката на обекта (средно)

| Предмет | Диапазон на разходи | Влияние върху график |

|---|---|---|

| Изчистване на терен | 1 500–5 000 долара | 1–2 седмици |

| Заливане на основата | 7 000–25 000 долара | 3–4 седмици |

| Комуникации | $4k–$15k | 2–6 седмици |

Най-добри практики за готовността на земята препоръчват завършването на подобренията в инфраструктурата преди доставката на модулите, за да се предотвратят забавяния, свързани с времето.

Проектиране, планиране и разрешения: Съгласуване на персонализацията с изискванията за съответствие

Сътрудничество с архитекти и производители по планировката на модулни къщи

Когато собствениците се включат рано заедно с архитекти и производители, това помага за създаването на проекти, които наистина работят както визуално, така и в заводската среда. Модулните къщи се различават от обичайното строителство, защото веднъж построени, не може да се върнат назад. Хората трябва да решат размерите на стаите, местоположението на прозорците и начина, по който ще бъдат разположени водопроводните и електрическите инсталации, преди нещата да бъдат изпратени. Повечето големи производители днес започнаха да използват онези интересни 3D моделиращи програми. Те могат буквално да експериментират как модулите се съчетават на екрана, правейки промени по време на процеса, без да се притесняват да повредят нещо важно от структурна гледна точка. Някои компании дори позволяват на клиентите да видят как ще изглежда дома им, сглобен във виртуалното пространство, преди да започне производството.

Включване на персонализация при спазване на фабричните ограничения

Модулното строителство определено дава известна свобода при проектирането, но има ограничения, тъй като всичко трябва да се вписва в стандартните производствени спецификации. Искате високи тавани или необичайна планировка? Вероятно ще се наложи първо да получите одобрение от инженерна гледна точка. Най-новият доклад за модулно строителство посочва един важен факт: почти седем от десет проекта се забавят, когато хората се опитват да правят промени в последния момент, които просто не са съвместими с начина, по който се изграждат модулите. Вместо да се борят срещу системата, умните строители насочват своите персонализирани елементи към неща като цветове на боя, избор на подови настилки или различни видове фасадни материали. Такива промени позволяват на собствениците да персонализират пространството си, без да нарушават основните градивни елементи.

Осигуряване на одобрение на проекта и съгласуване с местните строителни норми

Модулярните къщи изискват одобрение от два различни източника, преди да започне строителството – инженерния персонал на производителя и местните строителни власти, които участват в процеса. Основните неща, които те проверяват, са стените спрямо изискванията за пожарна безопасност, колко добре къщата отговаря на целите за икономия на енергия и дали издържа на земетресения или силни ветрове, в зависимост от мястото, където ще бъде построена. Добра идея, която си струва да се запомни, е да поискате още в началото документите за сертифициране от ICC-ES от производителя. Получаването им навреме прави целия процес по-лек при взаимодействието с градските планери и други държавни служби, които трябва да дадат своите разрешения.

Процес на получаване на разрешения за модуларни къщи спрямо традиционни постройки

Модуларните проекти са изправени пред уникални предизвикателства при получаването на разрешения, тъй като инспекторите трябва да одобрят както фабрично произведените компоненти, така и монтажа на място. За разлика от традиционните строителни разрешения, които следват етапно одобрение, модуларните постройки често изискват:

- Сертификати за фабрична инспекция

- Одобряване на транспортни маршрути

- Разрешения за работа с кран

Ръководството за процеса на строително одобрение показва, че разрешенията за модулно строителство отнемат средно 18% по-дълго време поради нуждата от координация между отдели.

Чести закъснения при одобрението на разрешения и как да се избягват

Най-честите закъснения при модулни разрешения са поради изисквания за отстъпване в зонирането (22%), планове за връзка с комунални услуги (31%) и липсваща документация от производителя (47%). За намаляване на рисковете:

- Подавайте инженерни чертежи с печат още с първоначалното заявление

- Назначавайте срещи преди подаване на заявление с началника на пожарната и отделите по планиране

- Проверявайте съответствието на производителя с изискванията на държавните програми за модулно строителство

Активната комуникация с всички заинтересовани страни обикновено намалява сроковете за одобрение с 3–5 седмици в сравнение с реактивните подходи.

Основа, подготовка на площадката и координация с фабриката: Свързване на работата извън и на строителната площадка

Почистване, нивелиране и подготвяне на терена за основни работи

Правилната подготовка на площадката осигурява структурна цялост. Над 28% от закъсненията при модулни проекти се дължат на недостатъчно почистване на терена. Екипите трябва да премахнат отпадъци, да изравнят склонове над 15° и да стабилизират почвата, за да предотвратят проседане.

Избор на подходящ тип основа: плоча, краулспейс или мазе

Климатът и бюджетът определят избора на основа. Плочите струват с 20–30% по-малко, но нямат складово пространство, докато мазетата добавят 25 000–50 000 долара, но са подходящи за райони със замръзване. Според анкета на Националната асоциация за жилищно строителство (NAHB) от 2023 г. краулспейсовете са предпочитани в зони с наводнения поради повишените инсталации.

Синхронизиране на завършването на основата с графикa на производството във фабриката

Модулите обикновено се изграждат за 8–12 седмици. Екипите на площадката трябва да завършат основите в рамките на този период — закъсненията водят до такси за складиране във фабриката от 500–1000 долара/ден. Седмичните актуализации между производителите и строителите минимизират графични конфликти.

Проследяване на строителството на модулни къщи в производствената зала

Цифрови инструменти като BIM софтуер позволяват на собствениците да следят напредъка чрез 3D модели. Инспектори проверяват предварителната инсталация на електрически/водопроводни системи преди доставката, което намалява грешките на строителната площадка с 37% (Институт за модулно строителство, 2023).

Осигуряване на комуникация в реално време между строителя и производителя

Лошата комуникация причинява 42% от закъсненията в модулните проекти. Прилагайте споделени платформи за промени в проекта и назначете един контакт за решаване на проблеми в рамките на 24 часа, съгласно най-добри практики при строителство извън площадката.

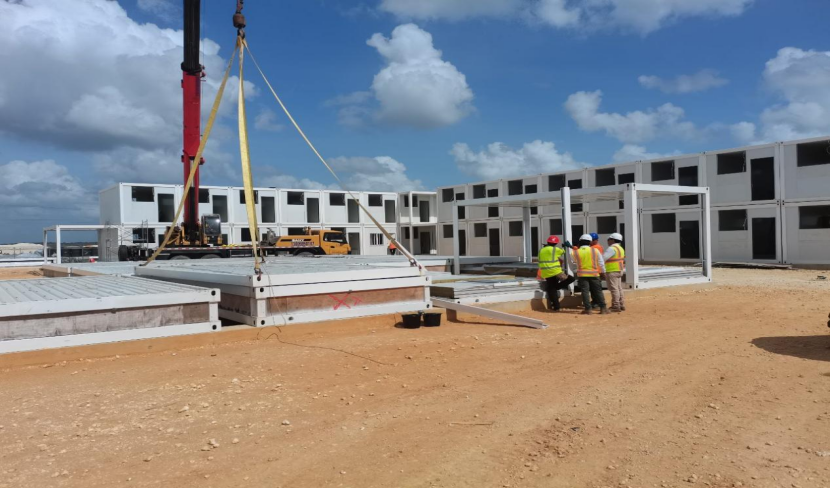

Доставка, монтаж и структурна интеграция на модулни блокове

Логистика по транспортирането на модулни компоненти до обекта

Подвижните части за модулни къщи изискват внимателно планиране, тъй като често са по-големи от обикновения товар. Заводите работят в тясно сътрудничество с логистичния персонал, за да определят най-добрите маршрути, които избягват онези досадни ниски мостове или тесни пътища. Около една четвърт от всички проекти за модулно строителство имат закъснения, когато пропуснат правилната проверка на маршрутите предварително. Повечето компоненти днес се превозват с флатбет камиони и много компании следят цели конвои чрез GPS системи, така че всичко да пристигне точно навреме на строителните площадки, без да причинява проблеми с трафика. Водещите производители започнаха да оптимизират операциите си, като създават детайлирани планове за монтаж още от самото начало, което намалява количеството материал, който трябва временно да се съхранява на строителните площадки по време на инсталирането.

Изисквания за настройка на кранове и безопасностни протоколи по време на монтаж

Сертифицирани кранови оператори позиционират модулите с точност до ¼ инч, използвайки индикатори за момент на натоварване и системи за стабилност на аутригери. На строителните площадки се изискват зони за свободно движение на 360° и постоянно наблюдение на скоростта на вятъра — при вятър над 20 мили в час дейностите се преустановяват според стандарта на OSHA. Екипите провеждат ежедневни проверки на оборудването и одити на въжетата и скобите, за да се предотвратят злополуки по време на вдигане.

Свързване на модули и запечатване на конструктивни връзки

След поставяне с кран, екипажите закрепват модулите чрез предварително заварени стоманени плочи, като запазват непрекъснатостта на конструктивния товарен път. Пяна се напръсква за запечатване на съединенията по покрива, а компресионни уплътнения осигуряват водонепроницаемост на стенните фуги. Топлинни камери правят сканиране, за да потвърдят непрекъснатостта на топлоизолацията, преди да бъдат монтирани вътрешните повърхности.

Тенденция: Използване на GPS и IoT проследяване в логистиката за доставка на модулни сгради

67% от производителите на модулни сгради в момента вграждат IoT сензори в стенни ниши, за да следят ориентацията на компонентите по време на транспортиране. Сигнали за наклон в реално време предотвратяват проникването на влага в подовите системи, докато геозонното проследяване на доставките гарантира пристигането на модулите в правилната последователност за ефективна сглобка.

Финални инспекции, свързване към комунални мрежи и готовност за заселване

Завършване на интериорната отделка и окончателни работи след сглобката

След като всички модулни секции бъдат закрепени, работниците започват с финалните интериорни довършителни работи. Те запечатват ставите на гипсокартоните с последния слой паста, поставят луксозни винилови плочки, които лесно се закачат една за друга, и монтират персонализирани кабинети. Според проучване на NAHB от 2023 година, около седем от всеки десет купувачи на модулни къщи в крайна сметка поискват някаква промяна в аранжимента, докато се извършват тези интериорни детайли. Това означава, че хората, работещи на строителната площадка, трябва да поддържат плътна връзка с колегите си в завода, за да могат правилно да реализират всички тези корекции.

Свързване на комунални услуги: септична, вода, електричество и газ

Лицензирани изпълнители едновременно свързват домашните системи към общинските услуги, докато продължава вътрешната работа. Модулните инсталации изискват специализирано пренасочване за предварително проектирани тръбопроводни канали в стени/подове. Проверката под налягане на газовите тръби (45–60 PSI) и водните системи (80–100 PSI) потвърждава липсата на течове, преди изолацията и гипсокартонът да скрият тръбите.

Назначаване на окончателни проверки и отстраняване на задачите от списъка за довършване

Местните строителни отдели обикновено провеждат от 3 до 5 фазирани проверки за модулни къщи, спрямо 7–9 за построени на място. Често срещаните корекции след монтажа включват балансиране на въздушния поток в климатичната система (необходимо в 38% от проектите – Институт за модулно строителство 2023 г.) и корекции в подравняването на фасадните панели. Професионален съвет: Назначете проверките на електрическата и водопроводната инсталация преди монтажа на гипсокартон, за да избегнете скъпи разглобявания.

Получаване на сертификата за ползване и подготовката за заселване

Получаването на последното одобрение изисква преглед по 11-точков списък, включващ неща като аварийни изходи, парапети и местоположението на детекторите за дим. Според ръководството за разрешения от Archistar, което използваме като справочен източник, повечето закъснения при проектите за модулно строителство всъщност се дължат на недовършени ландшафтни работи или алеи, а не на проблеми със самата конструкция на къщата. След като получите зелена светлина, не забравяйте първо да направите тест за влажност на дървените материали. Целта е показанията да останат под 12% съдържание на влага, за да се избегнат проблеми с плесен по-късно, когато бъдат внесени мебелите.

ЧЗВ

Какви са ключовите фактори, които трябва да се имат предвид при избора на място за модулни къщи?

Имайте предвид достъпността, състоянието на почвата, наличността на комунални услуги и пътищата за транспортиране на модулите. Плоска земя близо до пътища е идеална, за да се спести време за подготовка.

Влияят ли зонирането по различен начин върху модулните къщи в сравнение с традиционните къщи?

Законите за зониране могат да се различават за модулни къщи по отношение на размера и естетиката. Проверете с местните органи за конкретните правила, приложими за модулни конструкции.

Какво е значението на провеждането на проучвания за осъществимост на обекта?

Проучванията за осъществимост помагат да се идентифицират потенциални проблеми с наклона, почвата и достъпа, предотвратявайки надвишаване на бюджета и гарантирайки жизнеността на проекта.

Как повлиява координирането на комуналните услуги върху строителството на модулни къщи?

Правилното координиране с доставчиците на комунални услуги по време на проектния етап предотвратява последващи преустройства след завършване на строителството, намаляващо проблемите с връзката и осигуряващо инфраструктура, подходяща за модулни къщи.

Съдържание

- Оценка на подходящи локации за модулно строителство на къщи

- Разбиране на законите за зониране и ограниченията за използване на земя за модулни къщи

- Провеждане на проучвания за приложимост на обекта: наклон, почва и достъп

- Осигуряване на инфраструктура и достъп до комунални услуги, подходящи за модулно строителство

-

Проектиране, планиране и разрешения: Съгласуване на персонализацията с изискванията за съответствие

- Сътрудничество с архитекти и производители по планировката на модулни къщи

- Включване на персонализация при спазване на фабричните ограничения

- Осигуряване на одобрение на проекта и съгласуване с местните строителни норми

- Процес на получаване на разрешения за модуларни къщи спрямо традиционни постройки

- Чести закъснения при одобрението на разрешения и как да се избягват

- Основа, подготовка на площадката и координация с фабриката: Свързване на работата извън и на строителната площадка

- Доставка, монтаж и структурна интеграция на модулни блокове

- Финални инспекции, свързване към комунални мрежи и готовност за заселване

-

ЧЗВ

- Какви са ключовите фактори, които трябва да се имат предвид при избора на място за модулни къщи?

- Влияят ли зонирането по различен начин върху модулните къщи в сравнение с традиционните къщи?

- Какво е значението на провеждането на проучвания за осъществимост на обекта?

- Как повлиява координирането на комуналните услуги върху строителството на модулни къщи?